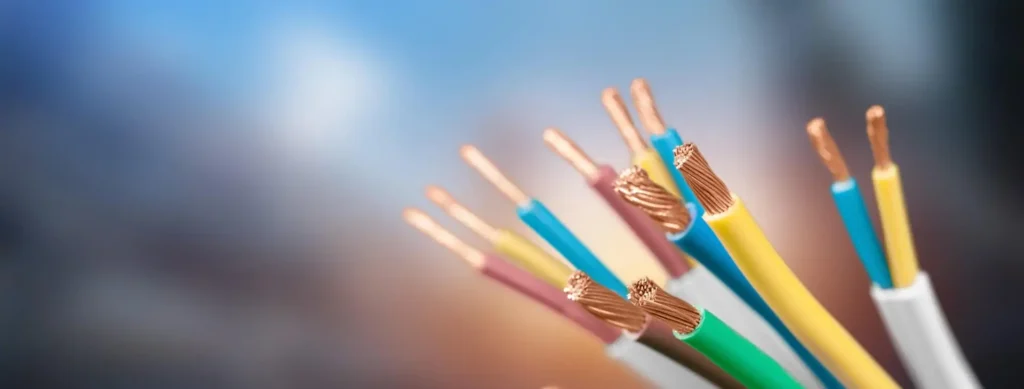

Building wire and cable play a crucial role in the construction of nearly every commercial, industrial, and residential property worldwide. Commonly referred to as branch circuit wiring in homes and businesses, these products facilitate the flow of electrical current to power various devices within a building or dwelling.

Construction

Conductor

The conductors, responsible for carrying the current, consist of stranded, high-conductivity plain annealed copper wires conforming to class 2 in BS 60228 and IEC 60228. Alternatively, aluminum stranded compacted conductors are also utilized.

Insulation

The cable’s rated voltage level is contingent on the dielectric strength and thickness of the insulation. Standard wiring cables employ PVC grade Type TI 1 of BS 7655 (formerly BS 6746) for insulation, suitable for a maximum continuous conductor operating temperature of 70˚C.

Characteristics

Standards

Core Identification

For cables with Single core – Red, Black, Yellow, Blue, Yellow/Green are the most commonly used colored wires

Applications

Designed for domestic wiring, this cable can be installed in fixed installations in dry or damp premises, either clipped to the surface, on trays, or in free air where the risk of mechanical damage is not a concern.

It is suitable for laying in conduit or trunking when mechanical protection is required.

Construction

The conductor is made of annealed high purity of copper, having excellent property of electrical conductivity as well as high mechanical flexibility.

PVC (Polyvinyl Chloride) is used for insulation and sheathing requirements since it is suitable for various flexible applications like high electrical, mechanical and thermal properties.

Construction of the Flexible Cables

Conductor | It is Current carrying component of the cable. |

Materials | Made of Flexible copper conductors of class-5 complying to BSEN 60228. |

Insulation: | The act of separating a body from others by nonconductors, so as to prevent the transfer of electricity or of heat; also, the state of a body so separated. |

Materials | Made of PVC Type TI 2 materials complying to BSEN 50363-3. |

Sheathing: | Used for Protective casing or covering. |

Materials | Made of PVC Type TM-2 materials complying to BSEN 50363-4-1. |

Characteristics

· Temp Rating | PVC Insulation suitable for continuous operating temp. up to 70 degree Centigrade |

· Minimum Bending Radius: | 4 x Cable Diameter |

|

|

Standards

· BS 6500: | for sizes up to 2.5mm2 |

· BS 7919: | for sizes up to 4mm2 |

· BSEN 60228: | Flexible class 5 copper conductors |

· BSEN 50363-3: | Insulation PVC Type TI 2 |

· BSEN 50363-4-1: | Sheathing PVC Type TM 2 |

Core Identification

2 Core | : Blue and Brown |

3 Core | : Green/Yellow, Blue and Brown |

4 Core | : Green/Yellow, Blue, Brown and Black or Green/Yellow, Brown, Black and Grey |

5 Core | : Green/Yellow, Blue, Brown, Black and Grey |

Applications

It is used in extension reels for connection of computers/Laptops in offices, in household appliances such as washing machines, spin dryers and refrigerators and also for all kinds of outdoor works like lawn movers, vacuum cleaners & for lighting and power equipment.

We supply complete range PVC Flexible Cables.